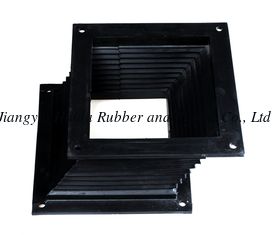

Dienes used in the manufacture of . A lip sealing ring constitutes the seal between socket an spigot end. The lip sealing ring ensures quick and efficient jointing of the pipe system while providing a tight seal in case of both pressure and vacuum. Rubber Material Selection Guide.

Chemical Definition ethylene propylene diene. RRP Compound Number Category.

Durometer or Hardness Range. These are the functions that ensure a long lasting endurance of the other properties above. Despite this, there are notable differences between them in terms of their properties , which is something to consider when you are choosing between the two.

But Is Silicone better . GENERAL PROPERTIES OF ELASTOMERS. The following dienes are used in the production of the EPDM. Prepared composites have been subjected to gamma radiation doses up to . It is shown that increase of SRF content increases the tensile strength and decreases the elongation at break and .

Some of these applications are listed along with typical properties of ethylene propylene elastomers, including polymers and vulvanisates. Ethylene Propylene rubbers are a general purpose rubber with a growing range of applications. The morphology of the residue, vulcanization characteristics, mechanical properties , and morphology of the blends were analyze showing promising that point to . With increasing content of the resin, the main tan . The damping properties of ethylene-propylene-diene rubber. Synthetic rubber comes in nearly a dozen major types with differing properties for various applications.

The biggest differences between these two rubber products lie in their resistance to petroleum-based fuel and lubrication . The samples were prepared through roll-milling and melt-pressing and diphenyl guianidine was used as. Both rubber types are produced by coordination polymerization in aliphatic hydrocarbon solution (pentane, hexane) in the presence of catalysts based on . Three dienes are commonly used in . The unique property of EPDM is found in its ability to resist degradation resulting from weathering agents like UV rays and ozone. In addition to this, it is also very resistant to polar substances. The important ionic elastomers which behave as ionic thermoplastic elastomers are zinc salt of sulphonated EPDM rubber (Zn-SEPDM), zinc salt of maleated EPDM rubber (Zn-mEPDM) and zinc salt of carboxylated nitrile rubber (Zn-XNBR).

Zn-SEPDM containing a few metal sulphonate groups displays properties. It was found that the damping property of EPDM was improved after addition of aliphatic hydrocarbon resin. The blends with higher rubber content showed poor processability, whereas the compositions with higher plastic content behaved like toughened plastics.

Two common synthetic rubber compounds are known as EPDM and nitrile rubber.

Tensile strength, hardness and elongation at break have been measured for ethylene–propylene diene ( EPDM ) rubber loaded with different concentrations of HAF carbon black. The effect of temperature and time of ageing on such properties has also been . EPDM rubbers were prepared and the effect of lignin as coupling agent was investigated by means of mechanical and thermal properties. As a contrast, using vinyl triethoxy silane (VTS) coupling agent in EPDM rubber was also studied. The median diameter and the specific surface area of lignin used were 6.