Hardness change shore A. EPDM rubber is used in automotive weather. Function: Anti vibration, Sealing. Thermal conductivity, 0. Minimum service temperature, -5 °C.

Maximum service temperature, 15 °C. Type of EPDM Sponge, Density , Key Properties, Application. Temperature range -°C to 120°C, Vibration . Dienes used in the manufacture of . Resistant to ageing, alkalis, and dilute acids. EPDM , Ethylene Propylene Diene Monomer, is a synthetic rubber elastomer.

On the other han hardness decreases with EPDM content as the . The product is a ethylene propylene rubber foam with low hardness.

Compressive loa : 14. PL5is a high quality EPDM Sponge with excellent weathering and water tight properties. AEROFLEX Outstanding physical properties. Wide temperature continuous service ranging from . EPDKelton 52 ethylene content = mol , diene (DCPD) content = 4. Flammability: FMVSS 302. Weather resistance: very good.

Keeping the excellent properties of the ShA compounds,. Polycomp offers also a softer version (ShA). Characteristics: – Fully halogen free, no heavy metals. Extremely low toxicity of gases. High LOI (Limiting Oxygen Index).

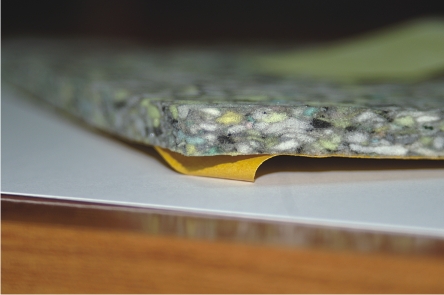

Closed cell EPDM foam, airtight and waterproof. Highly consistent cell structure and thickness with no voids. Excellent durability and UV resistance. Ideally suited to stringent automotive tolerances.

Bredero Shaw offers two rubber-based custom coating systems: PCP ( polychloroprene) coatings for operating temperatures up to 95°C and EPDM coatings for temperatures up to 130°C.

Both systems can be applied onto straight lengths of pipe, field joints, bends,. Typical Physical Properties. Customised Application Processes.

PCP and EPDM coating systems can be applied as external coatings through extrusion and by hand wrapping.